sjzyongchang@sjzycsd.cn

sjzyongchang@sjzycsd.cn  +8615075161011

+8615075161011

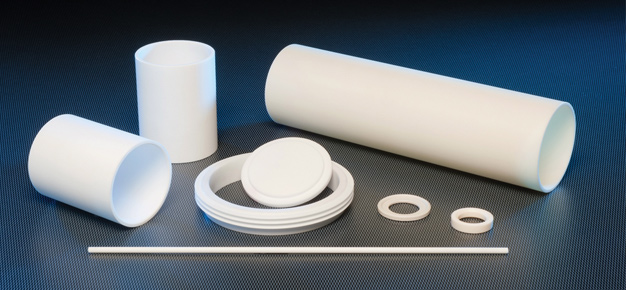

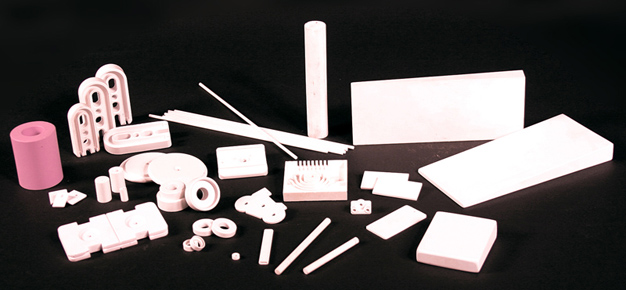

Modern alumina (Al2O3) products are among the strongest and hardest of all ceramic materials. They also have a high dielectric strength, and at elevated temperatures such as those encountered in many applications, their electrical resistance is excellent. Alumina ceramics also feature very high mechanical strength, high thermal conductivity, and high resistance to chemical and corrosion attack at room and elevated temperatures. Further, this valuable class of materials can be made extremely hard - second only to diamond on the Mohs scales for resistance to wear and abrasion.

Many of alumina outstanding properties can be enhanced through variations in manufacturing methods and in chemistry. Associated Ceramics has earned a reputation for achieving dimensionally accurate alumina parts with excellent quality and reproducibility. The following table describes many common alumina bodies; we can work with other formulations as well.

Table converts to a left/right scrolling table when viewed on mobile devices or smaller screens.

| ACT Material Code > | AC-AL1090 | AC-AL850 | AC-AL900 | AC-AL920 | AC-AL940 | AC-AL960 | AC-AL980 | AC-AL8020 | AC-AL998 | AC-ZTA | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Description > | 80% | 85% | 90% | 92% | 95% | 96% | 98% | 99.5% | 99.80% | Zirconia Toughened Alumina | |

| Color | - | White | White | White | White | White | White | White | Ivory | Ivory | White |

| Density | g/cc | 3.40-3.45 | 3.45-3.50 | 3.55-3.60 | 3.60-3.65 | 3.70-3.75 | 3.70-3.75 | 3.75-3.80 | 3.75-3.85 | 3.90-3.95 | 4.00-4.05 |

| Porosity | % | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 |

| Flexural Strength | psi (MPa) | 40,000 (276) | 42,000 (290) | 45,000 (310) | 47,000 (324) | 48,000 (331) | 50,000 (345) | 52,000 (358) | 50,000 (345) | 54,000 (372) | 60,000 (414) |

| Compressive Strength | psi (Mpa) | 260,000 (1,792) | 280,000 (1,930) | 300,000 (2,068) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) |

| Tensile Strength | psi (MPa) | 21,000 (145) | 22,000 (152) | 30,000 (205) | 32,000 (221) | 30,000 (205) | 32,000 (221) | 35,000 (241) | 32,000 (221) | 40,000 (276) | 42,000 (290) |

| Elastic Modulus | psi x 106 (GPa) | 32 (221) | 32 (221) | 40 (275) | 42 (290) | 44 (303) | 44 (305) | 50 (345) | 50 (345) | 54 (372) | 50 (345) |

| Fracture Toughness | MPa/m | 3-4 | 3-4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 |

| Dielectric Strength | Volts/mil | 250 | 250 | 210 | 210 | 210 | 210 | 220 | 210 | 220 | 210 |

| Dielectric Loss Tangent | @ 1 MHz | 0.0004 | 0.0004 | 0.0004 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0005 |

| Thermal Conductivity | W/m°K | 16.0 | 16.0 | 17.0 | 20.0 | 22.0 | 22.5 | 27.0 | 27.0 | 30.0 | 27.0 |

| Coefficient Of Thermal Expansion | 1 x 10-6/°C | 7 | 7 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Safe Use Temperature | °F °C | 2400 1315 | 2600 1425 | 2700 1480 | 2850 1565 | 3000 1650 | 3000 1650 | 3100 1700 | 3200 1750 | 3100 1700 | 2700 1480 |

Blank filler (skeleton)

Alumina, except artificial corundum, alumina ceramics

1. Brown aluminum oxide abrasive

2. Calcined aluminum oxide powder Calcined aluminum oxide powder, raw material for ceramic tile production, cas code: 1344-28-1

Aluminum oxide, chemical symbol: Al2O3, molecular weight 102. Pure aluminum oxide is a white amorphous powder, which is also called bauxite in mining, ceramics and material science. Its density is 3.9-4.0g/cm3, melting point is 2050 ℃, boiling point is 2980 ℃, and it is insoluble in water. It is an amphoteric oxide, which can be dissolved in inorganic acid and alkaline solutions. Aluminum oxide has 9 crystalline states, mainly including α Type and γ Type B has two variants, which can be extracted from bauxite in industry. It is the main raw material in aluminum electrolysis production. As a typical material in structural ceramics, aluminum oxide is usually applied to structural parts that need to bear mechanical stress. Especially, it can be used under harsh conditions due to its high melting point, high hardness, corrosion resistance, good electrical insulation and other characteristics. Alumina in nature is called corundum( α- Al2O3) is the product of volcanic eruption. It is colorless crystal in rocks, and can also be dyed with other aluminum oxide impurities (chromium oxide, iron oxide, etc.) into colored crystals. Red is called ruby, and other corundum gems are called sapphires.

Industrial alumina is the dehydration product of various alumina hydrates after thermal decomposition. They form a series of homogeneous and heterogeneous crystals, some of which are dispersed and some of which are transitional.

The structural types of commonly used alumina are as follows:

? α- Alumina. Also known as corundum structure, it is the most stable of alumina crystal forms. It is a representative structure of M2O3 type oxides. The corundum type structure has the most densely packed cubic oxygen atom layer, and 2/3 of the octahedral coordination gaps between oxygen atoms are filled by metal atoms. in other words, α- Aluminum oxide is an octahedral hexa coordinated aluminum atom surrounded by six oxygen atoms. Since the ion radius of aluminum ion is the smallest M2O3, it is closely combined with oxygen ion to become the highest hardness trivalent metal oxide.

α Type A aluminum oxide is insoluble in water and acid, and is the basic raw material for making aluminum metal; It is also used for making various refractory bricks, refractory crucibles, refractory pipes, and high-temperature experimental instruments; It can also be used as abrasive, flame retardant, filler, etc; High-purity α Type A alumina is also the raw material for producing artificial corundum, artificial ruby and sapphire; It is also used to produce the board base of modern large-scale integrated circuits.

? γ- Alumina, γ- Al2O3 is the excessive aluminum oxide generated during dehydration of aluminum hydrate such as boehmite and aluminum hydroxide. It is converted into α- Al2O3 is a compact structure with great sintering shrinkage. Judging from the structure, it has holes, good adsorption capacity for other substances, large surface area, and high adsorption characteristics for water and other substances, so it can be used as adsorbent and desiccant. Its chemical properties are relatively active, and it is easy to react with acid or alkali solutions.

? β- Alumina. Strictly speaking, β- Al2O3 does not belong to alumina. The chemical composition can be approximately represented by MeO 6 Al2O3 and Me2O Al2O3. (MeO refers to alkaline earth metal oxides such as CaO, BaO and SrO, and Me2O refers to alkaline metal oxides such as Na2O, K2O and Li2O.) β- Al2O3 is only a kind of high content aluminate compound, which has obvious ionic conductivity and relaxation polarization, large dielectric loss and poor electrical insulation performance. The aluminum oxide commonly produced for aluminum electrolysis in aluminum oxide production is α- Al2O3 and γ- Al2O3 mixture.

Aluminum oxide for aluminum electrolysis production mainly consists of α- Al2O3 and γ- Al2O3 composition. The quality of aluminum oxide directly affects the purity of metal aluminum obtained and the technical and economic indicators of aluminum electrolysis production. Therefore, alumina, as the raw material for aluminum electrolysis, has certain requirements for its chemical purity and physical properties.

1. Chemical purity of alumina. In addition to mainly containing Al2O3, alumina often contains a small amount of impurities such as SiO2, Fe2O3, Na2O and H2O. Aluminum oxide used for aluminum electrolysis must have a higher chemical purity, because it contains oxide impurities (such as Fe2O3, SiO2, etc.) that correct electrical elements than aluminum. During electrolysis, these elements will first precipitate at the cathode and enter the metal aluminum, making aluminum impure. The metal oxide impurities (such as Na2O) in aluminum oxide, which are more negatively charged than aluminum, interact with the electrolyte and change the normal composition of the electrolyte, which is not conducive to electrolytic operation.

The residual crystal water in aluminum oxide is indicated by ignition loss. It is also a harmful impurity. HF is generated due to the interaction between water and AlF3 in electrolyte, which causes the loss of fluoride and pollutes the environment. In addition, when the aluminum oxide after burning or moisture absorption contacts with the high-temperature molten electrolyte, it will cause electrolyte explosion and splash, endangering the safety of operators.

Grade Al203 (%) SiO2 (%) Fe2O3 (%) Na2O (%) Burn loss (%)

Level I ≥ 98.6 ≤ 0.02 ≤ 0.03 ≤ 0.50 ≤ 0.8

Level II ≥ 98.5 ≤ 0.04 ≤ 0.04 ≤ 0.55 ≤ 0.8

Class III ≥ 98.4 ≤ 0.06 ≤ 0.04 ≤ 0.60 ≤ 0.8

2. Physical properties of alumina

In addition to strict requirements on chemical composition, aluminum oxide for aluminum electrolysis production also requires that aluminum oxide dissolve quickly in cryolite melt, the bottom of the electrolytic cell has less precipitation, the shell covering the electrolyte has good heat preservation, no moisture absorption in the air, less flying loss, good fluidity, and is convenient for transportation and automatic feeding of the electrolytic cell. All these properties depend on the physical properties of alumina. Indexes used for physical properties of alumina include: angle of repose α- Al2O3 content, bulk density, particle size, specific surface area, etc.

? Cape of repose. It refers to the inclination angle of materials naturally stacked on a smooth plane. Alumina with large angle of repose is easy to dissolve in the electrolyte, which can be well covered on the electrolyte crust during electrolysis, and the flying loss is also small.

? α- Al2O3 content. α- Al2O3 content reflects the calcination degree of alumina. The higher the calcination degree, α- The more Al2O3 content is, the more hygroscopic alumina α- The content of Al2O3 increases and decreases. Therefore, a certain amount of aluminum oxide for electrolysis is required α- Al2O3。 but α- The solubility of Al2O3 in electrolyte is better γ- Al2O3 is poor.

③ Bulk density. The bulk density of alumina refers to the mass of material per unit volume in natural state. Generally, alumina with small bulk density is favorable for dissolution in electrolyte.

④ Grain size. The particle size of alumina refers to the fineness. The particle size of alumina must be appropriate. If it is too coarse, it will dissolve slowly in the electrolyte, or even precipitate. If it is too fine, it is easy to fly and lose.

⑤ Specific surface area. The specific surface area of alumina refers to the total area of the sum of the external surface area and the internal surface area of the material per unit weight. It is an important indicator of material activity. Alumina with large specific surface area has good solubility and high activity in electrolyte, but it is easy to absorb moisture.

According to the physical properties of alumina, Al2O3 can generally be divided into three types: sandy, flour and intermediate. The physical properties of these three types of Al2O3 are quite different.

Sandy Al2O3 has small bulk density, large specific surface area, slightly small repose angle, and a small amount of α- Al2O3 has more and uniform coarse particles and high strength. Flour like alumina has large bulk density, small specific surface area and more α- Al2O3 has many fine particles and poor strength. The physical properties of intermediate alumina are between the two.